Laser engraving marking and etching service

We are specialists in laser engraving etching and marking solutions for industries ranging from manufacturing to the creative sector

Our company offers you the opportunity to have your specific marking thanks to its performance, high quality, and speed. This marking can be adapted to different industrial environments. Our team is committed to manufacturing automated markings that save time and money and help you reduce energy consumption.

Our products are used for either decorative purposes or industrial needs as an outsourcing service for businesses.

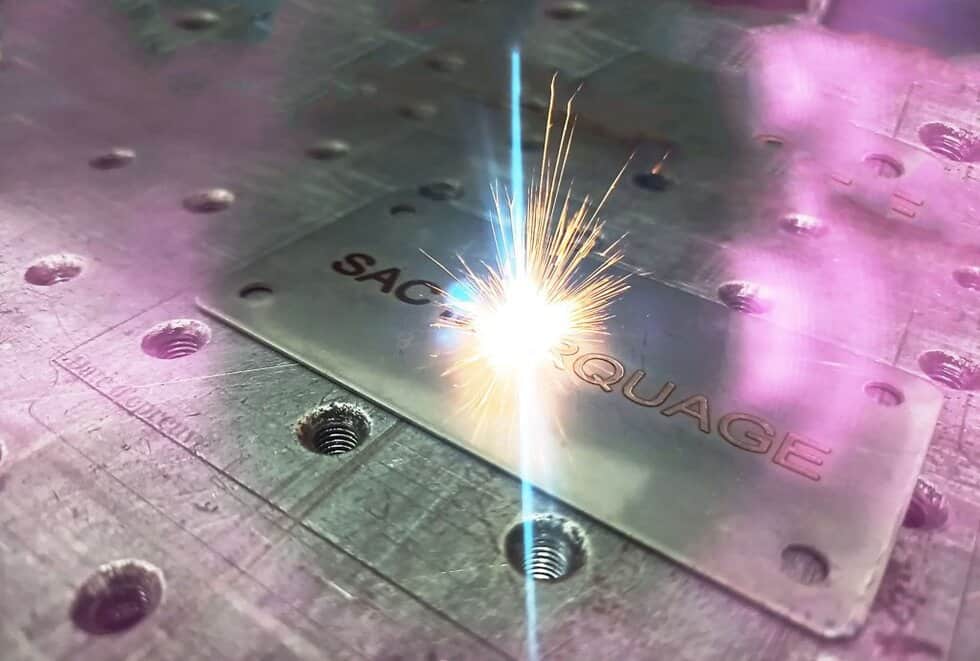

For metal surfaces, the sheets are cut by the laser beam before the top layer is removed and the marking process begins.

High-quality laser engraving

The experience we have acquired over the years has given us the opportunity to design and develop complete marking solutions for several industrial applications. This justifies the presence of our versatile marking machines in several large companies in different sectors such as: energy, aerospace and oil.

What's the difference between Laser engraving marking and etching?

There is a slight difference between laser marking and engraving and etching, depending on the penetration depth of the laser beam:

Marking is a process that burns the surface of the material, resulting in the removal of covering layers and discoloration under the effect of heat thereby altering its chemical characteristics, without damaging it There are different types of laser marking, the most common is laser annealing this process is suitable for QR code and barcode

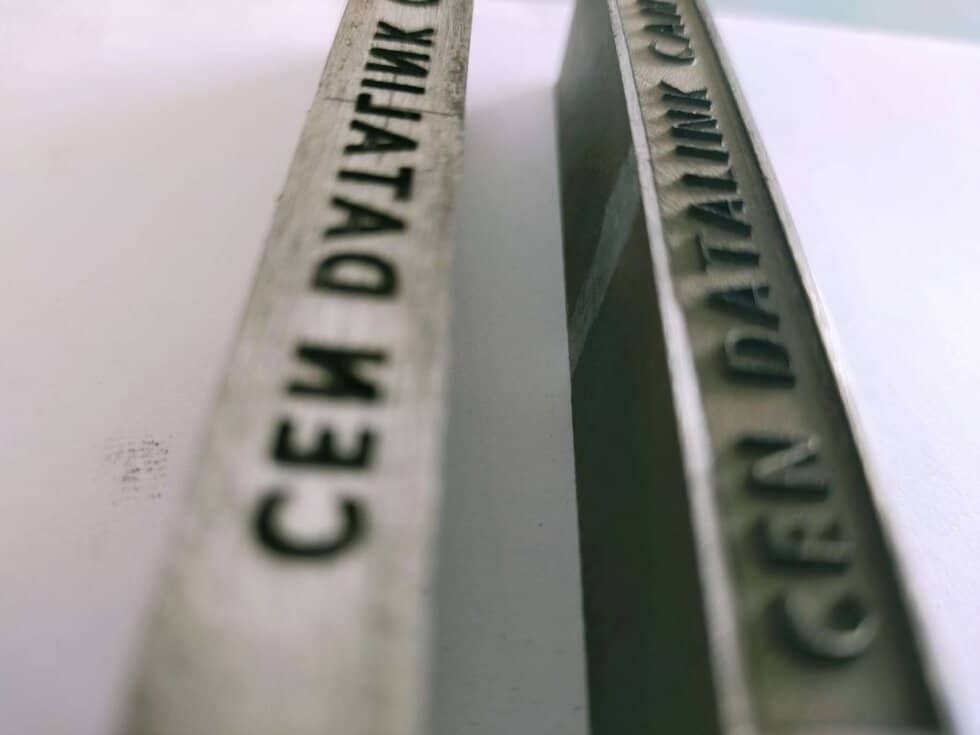

Engraving empties the surface of the metal, forming visible indentations on the surface, it requires more laser power and the mark is more durable and resistant. Ideal for metals used for serial numbers

Etching melts the surface of the metal under the effect of the laser beam heat. It also removes the surface but with a lesser depth than laser engraving

learn more about the difference

The choice of processing type is based on the material type, operating requirements, and objectives of the project.

Most laser marking machines can handle the etching ,engraving and marking processes

Customized laser engraving solutions

If you wish to carry out your personalized marking project, we will take care of it while guaranteeing you an excellent result that corresponds perfectly to your needs. Indeed, thanks to our experience, our team realizes a unique product no matter how complex the personalization is.

Read how this technique works in practice

Advantages of laser marking :

It offers several virtues such as:

- The procedure is direct and does not require a model

- the engraving is done on most materials metals like aluminum, gold, silver, stainless steel plastic, wood, glass, leather, etc

- It is possible that the marking is carried out on parts with complex forms

- High-precision engraving, offering a detailed and small format marking.

- Laser engraving is resistant to all thermal, mechanical, and chemical aggression…

- More advantages

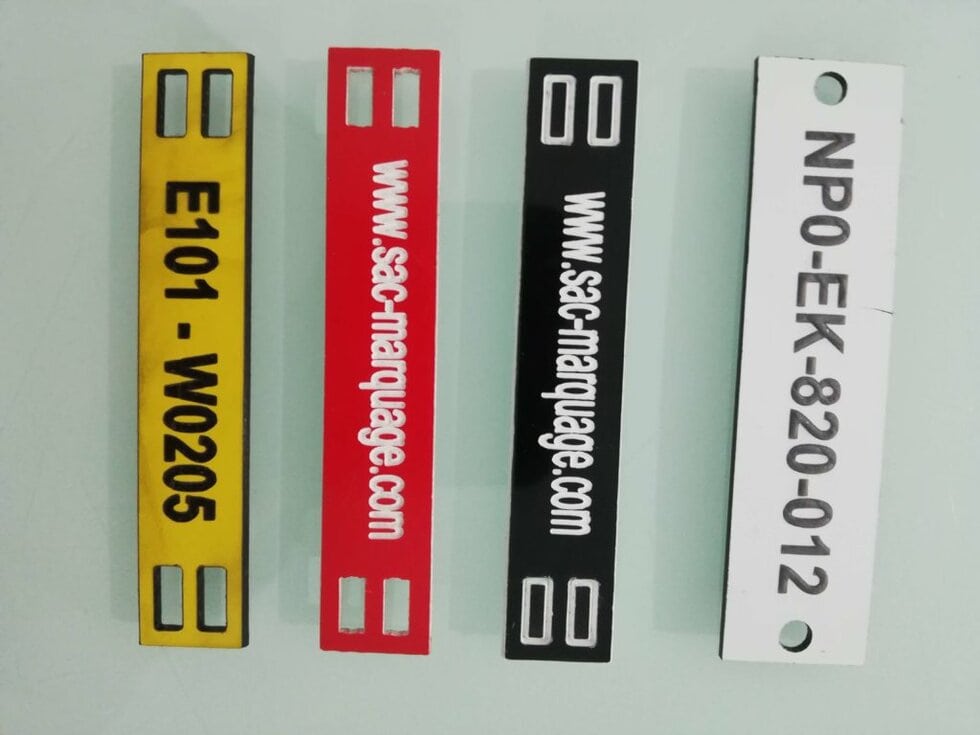

Typical applications

- Mechanical parts: bearings, gears, motors, etc.

- Electronics and electrical components: printed circuit, capacitor, resistor, etc.

- Signage and identification: sign, industrial nameplate, label, etc.

- Accessories and jewelry: watch, bracelet, etc.

- Industrial piping

- Automotive parts

- Hardware tools

- Handicraft

- Aerospace industry

- medical devices

Laser Marking and engraving sources

A wide variety of laser sources are available, factors such as the nature of the material, the speed of the process, and the depth of the mark determine which source is right for the requirements of the intended application.

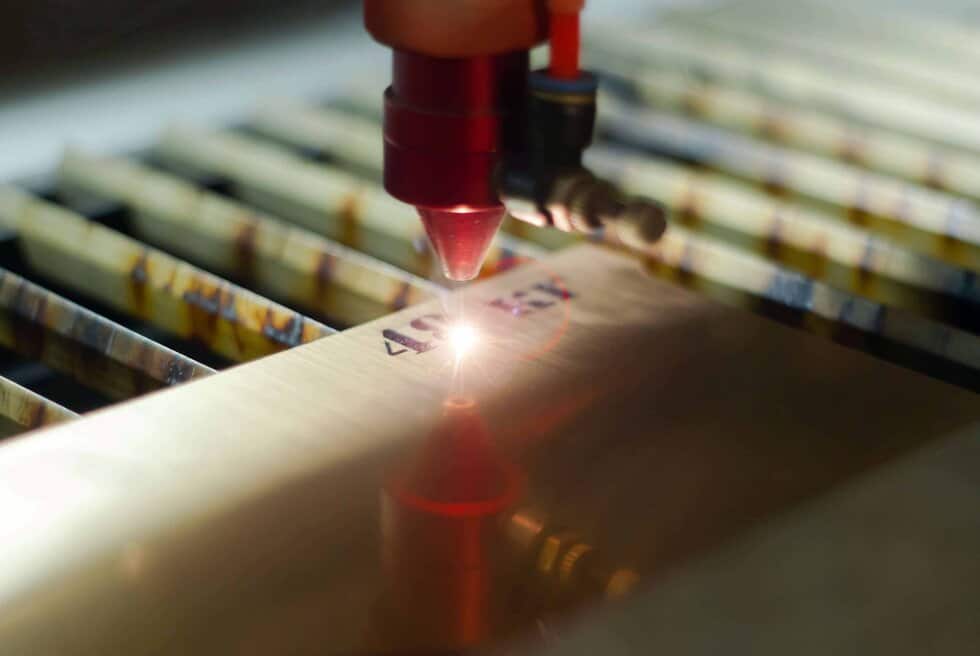

Fiber laser: uses a fiber-optic device to emit a laser beam. It can mark a wide variety of materials, mainly all metals and some plastics. engraving is carried out quickly

Co2 Laser: uses Carbon dioxide gas excited by electricity to produce the laser beam. It’s able to mark non-metallic materials including wood, paper, ceramics, plastics, textiles, etc

UV Laser: ultraviolet laser utilizes implanted crystals and generates no heat. It’s great for sensitive materials and parts made from glass and plastics. Extremely popular in medical and electronic devices, it does not damage materials as it is a cold marking solution.

If the application is laser cutting, it requires high laser power in Watts. Fiber laser technology is recommended for thin materials and fast, precise cutting, while CO2 laser technology is suitable for thick materials.

Do you have a project?

Our high-quality team is committed to providing you with high-quality customized nameplates and customized marking solutions for industrial and advertisement applications on all kinds of supports.

Learn more about our other engraving techniques, stainless steel engraving, and chemical engraving